Features

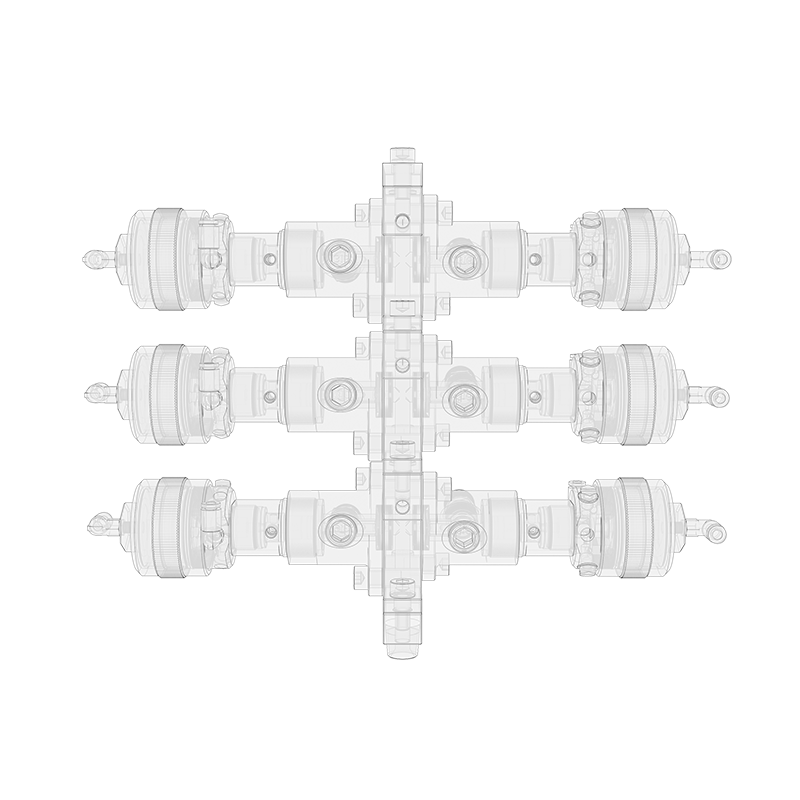

• Double-Acting Air Cylinder: Ensures fast and reliable switching performance.

• Robust Wetted Components: Constructed from 316 stainless steel, PTFE, and tungsten carbide for long-term chemical resistance and mechanical strength.

• Precision-Machined Valve Assembly: Rated for over 1 million cycles (depending on coating properties).

• Recirculating Valve Seat Design: Allows paint to continuously flow through the valve, reducing sedimentation and ensuring consistent flow.

• High-Durability Switch Base: Made of tungsten carbide and SUS316 for excellent life time and enhanced reliability.

• Flexible System Integration: Quick disassembly design for easy system expansion, reconfiguration, or maintenance.

• Multi-application adaptability: Suitable for a wide range of coatings and curing materials across multiple industries.

Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

|

Designation |

Value |

|

Max Material Pressure |

3000 psi (300 bar / 30 MPa) |

|

Max Air Pressure |

100 psi (7 bar / 0.7 MPa) |

|

Fluid Inlet Size |

1/4" PT (F) |

|

Fluid Outlet Size |

1/4" PT (F) |

|

Fluid Recirculation Size |

1/4" PT (F) |

|

Air Inlet Size |

Ø4 mm × 2.5 mm |

|

Operating Temperature |

5–50°C (41–122°F) |

|

Apply materials |

Primers, topcoats, varnish, polyurethane, epoxy, solvent-borne and water-based coatings |

|

Wetted Parts |

316 Stainless Steel, PTFE, UHMWPE, Tungsten Carbide |