Features

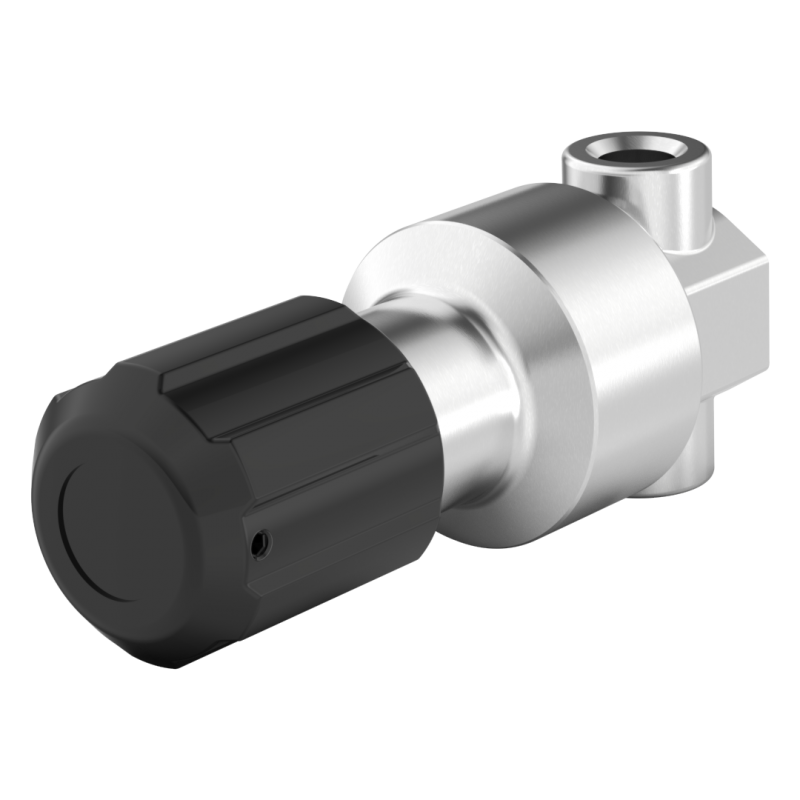

High Pressure Regulator

The high-pressure regulator is typically installed downstream of the pump or at

the outlet of a circulation system. Its purpose is to reduce the mainline

pressure and maintain consistent fluid pressure at the spray gun, atomizing

nozzle, or distribution valve. This ensures stable spray patterns and uniform

coating results.

Advantages

- Sensitive and accurate pressure

adjustment

- Maintains steady pressure to enhance finish quality

- Robust design with long service life

Features

High Pressure Back Pressure Valve

This mechanically operated back pressure valve is designed for use in

recirculating air-assisted spray systems. It maintains upstream pressure by

diverting excess material back to the reservoir once a preset threshold is

exceeded. This function is critical for keeping system pressure stable and

preventing over-pressurization.

Advantages

- Automatically relieves excess pressure

- Ensures consistent upstream flow in closed-loop systems

- Reliable operation with minimal maintenance

Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

TECHNICAL DATA TABLE (Both Models):

|

Max Pressure |

2600 psi (18 MPa, 180 bar) |

|

Adjustable Pressure Range |

300–2500 psi (2–17 MPa, 20–170 bar) |

|

Max Flow |

8.1 GPM (30.8 L/min) |

|

Temperature Range |

32-194°F (0-90°C) |

|

Fluid Ports |

3/8" PT( f ) |

|

Wetted Parts |

316 stainless steel,PTFE |

|

Weight |

1.28kg |