Features

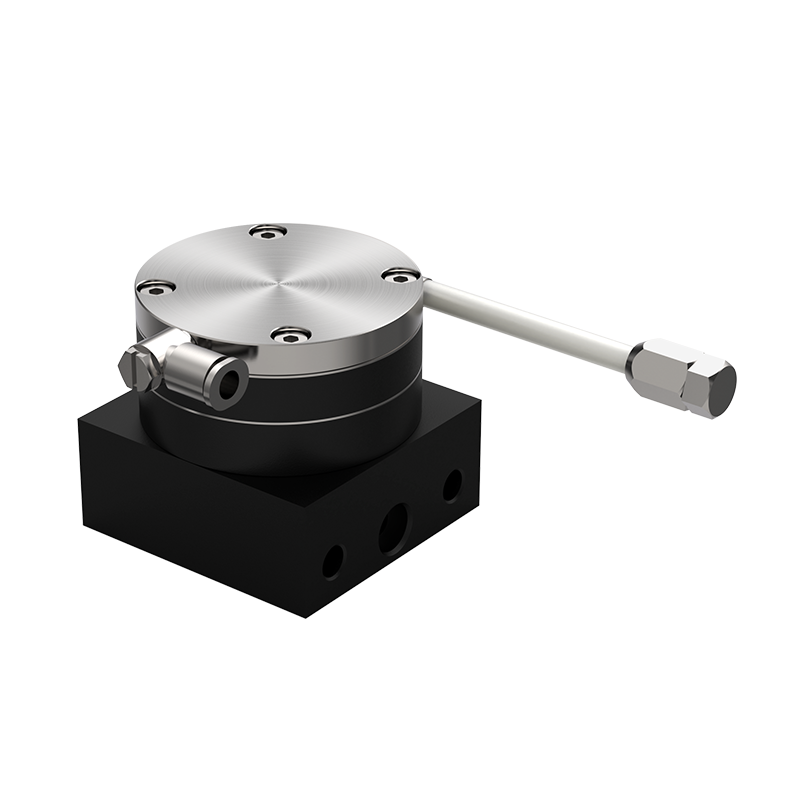

• Compact and lightweight design allows flexible installation and modular expansion.

• Switch base made from ultra-high-molecular-weight polyethylene (UHMWPE) and SUS316 stainless steel ensures high durability and reliability.

• Recirculating valve seat design allows coating materials to circulate through the valve to reduce pigment sedimentation.

• Precision-machined valve assembly rated for over 1 million cycles (fewer for abrasive materials).

• Valve body made of 316 stainless steel; valve seat constructed from durable POM.

• Straight-through fluid path design with polished interior and no dead corners. Connections are nylon-sealed—no PTFE tape required.

TECHNICAL DATA TABLE

| Max Material pressure | 21 bar |

| Recommended pressure range | 8 - 10 bar |

| Fluid inlet size | 6*8 |

| Fluid outlet size | φ6 |

| Fluid reflux size | 6*8 |

| Air inlet size | 4mm*2.5mm |

| operating temperature | 5 - 50° C(41 - 122° F) |

| Apply Materials | Primers, topcoats, varnish, polyurethane, epoxy, solvent-borne and water-based coatings |

| Wetted Parts | 316 stainless steel、PETP、FFKM、POM |