Features

- User-Friendly HMI & Plug-and-Play Functionality

- The system features standard physical buttons for spraying, cleaning, and fault clearance.

- One-Touch Cleaning: Automated cleaning cycle for proportioning valves, color-changing valves, flow meters, lines, and spray guns.

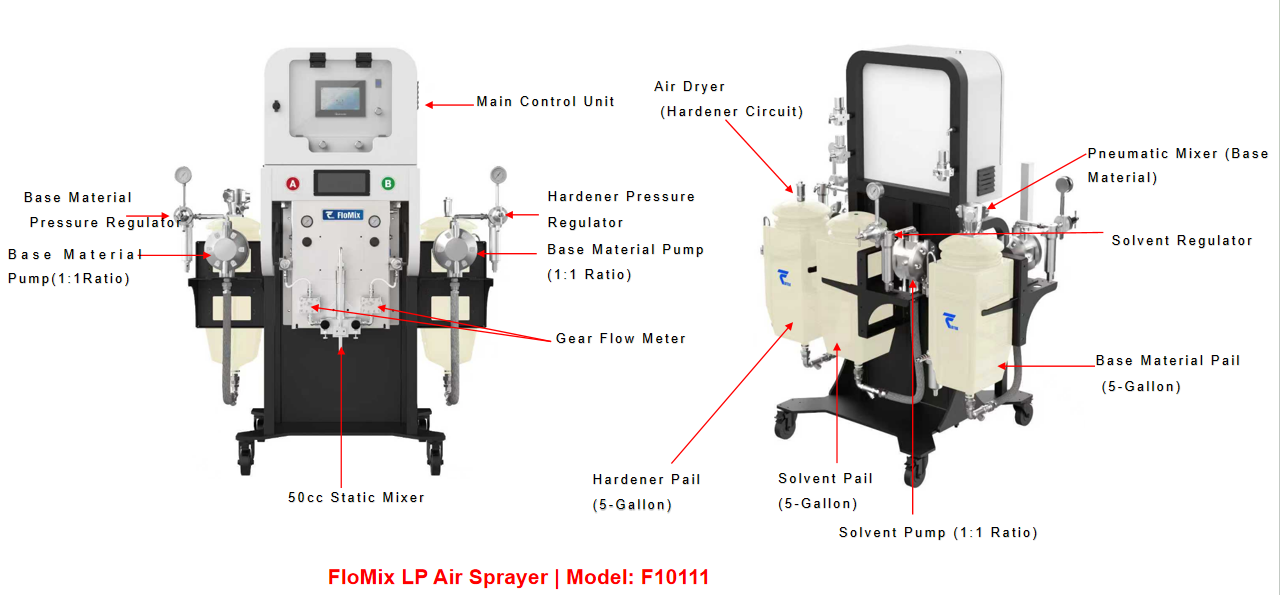

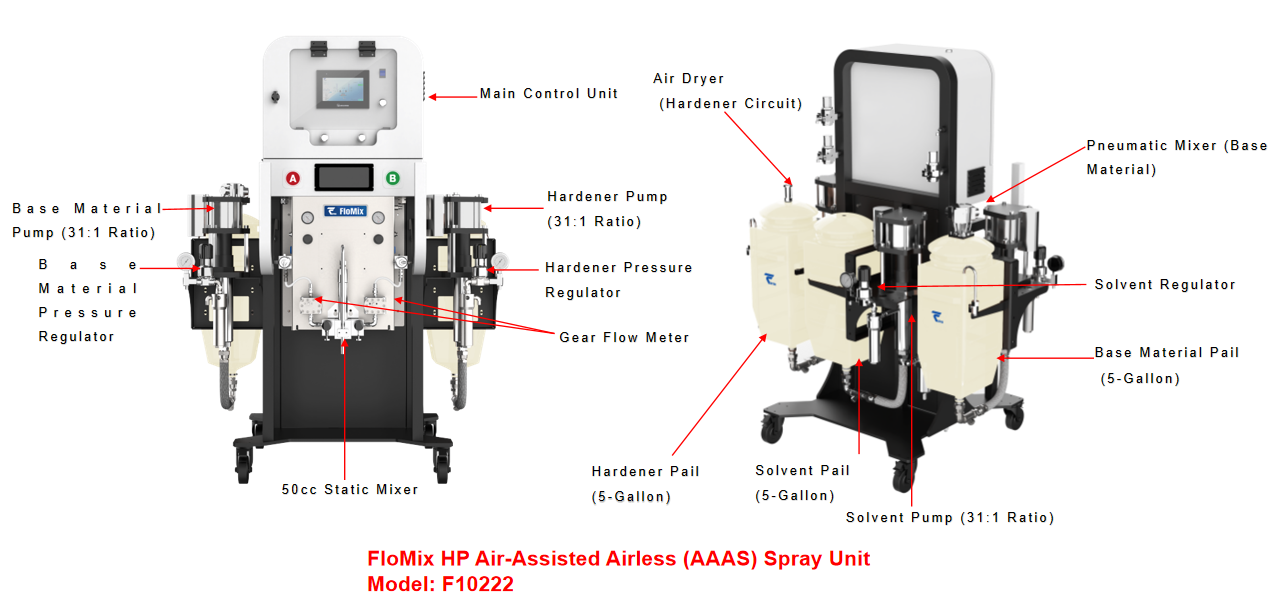

- Precision Gear Flow Meter (Standard): Ensures accurate volumetric flow measurement.

- Sampling Valve Block (Standard): Enables easy flow calibration and system verification.

- Manual Spray Gun Air Regulator and Port: Integrated pressure adjustment and connection point for manual spray guns.

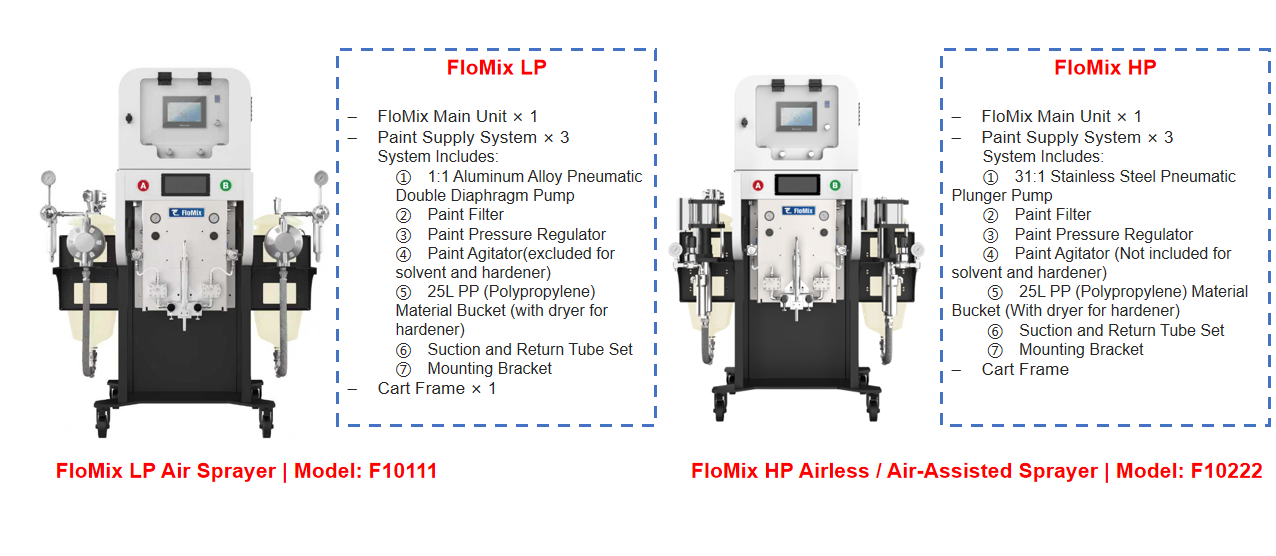

FloMix Pump-Integrated Proportioner

FloMix LP Air Sprayer |

Model: F10111

FloMix HP Air-Assisted Airless (AAAS) Spray Unit

Model: F10222

FloMix Pump Options:

1:1 Aluminum Alloy Pneumatic

Double Diaphragm Pump (Model DX200, Bare Pump)

Technical Specifications

|

Designation |

Value |

|

Compression Ratio |

1:1 |

|

Max Air Pressure |

7.0 bar (100 psi) |

|

Max Material Pressure |

7.0 bar (100 psi) |

|

Flow Rate @ 1 Cycle |

0.20 L (0.05 US Gal) |

|

Flow Rate @ 60 Cycles/Min |

12 L/min (3.17 US Gal/min) |

|

Recommended Max Continuous Cycle Rate |

25 Cycles/min |

|

Recommended Max Intermittent Cycle Rate |

60 Cycles/min |

|

Fluid Inlet Size |

ALU ¼" ST / ST ¼" BSPP Female |

|

Fluid Outlet Size |

ALU ¼" ST / ST ¼" BSPP Female |

|

Max Suction Lift |

4.6 m (15.1 ft) / 7.5 m (24.6 ft) |

|

Air Inlet Size |

G1/4" (BSPP) Female |

|

Fluid Regulator Air Tube Diameter |

Ø4 Tube |

|

Air Consumption/Cycle @ 6.9 bar/100 psi |

2.83 L (0.1 SCFM) |

|

Air Consumption @ 10 Cycles/min (6.9 bar/100 psi) |

28.3 L (1 SCFM) |

|

Air Consumption @ 30 Cycles/min (6.9 bar/100 psi) |

84.9 L (3 SCFM) |

|

Air Quality (ISO 8573.1 Class 3.3.2#) |

Water: 5°C @ 7 bar (940 ppm); Oil: 0.1mg/m³; Non-lubricated |

|

Noise |

71.2 dBA Leq |

|

Bare Pump Weight |

9.5 kg (20.94 lbs) |

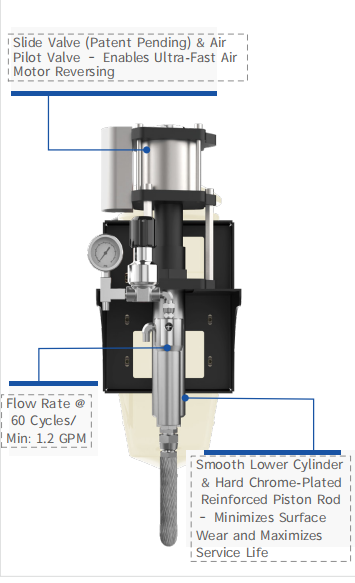

31:1 Stainless Steel Pneumatic Piston Pump

Technical Specifications

|

Specification |

MX1212 |

MX1231 |

|

Pressure Ratio |

12:1 |

31:1 |

|

Coating Flow @ 60 Cycles/Min |

1.2 GPM (4.3 L/min) |

1.2 GPM (4.3 L/min) |

|

Coating Flow Per Cycle |

2.4 oz (72 cm³/cycle) |

2.4 oz (72 cm³/cycle) |

|

Coating Inlet Connection |

3/4" NPS(m) |

3/4" NPS(m) |

|

Coating Outlet Connection (Pump) |

3/8" NPS(m) or BSP(m) |

3/8" NPS(m) or BSP(m) |

|

Coating Outlet Connection (Filter) |

1/4" NPS(m) or BSP(m) |

1/4" NPS(m) or BSP(m) |

|

Air Connection |

1/4" NPS(m) or 3/8" BSP(m) |

1/4" NPS(m) or 3/8" BSP(m) |

|

Wetted Parts |

Stainless Steel, Hard Chrome, Nylon, Silicon Carbide, PTFE, UHMWPE |

Same as MX1212 |

|

Max Material Pressure |

1,390 psi (96 bar) |

3,596 psi (248 bar) |

|

Compressed Air Consumption @ 20 Cycles/Min |

5.2 SCFM |

17.6 SCFM |

|

Noise |

96 dB |

97 dB |

|

Max Air Inlet Pressure |

116 psi (8 bar) |

116 psi (8 bar) |

|

Recommended Max Cycle Rate for Continuous Operation |

20 Cycles/Min |

Same as MX1212 |

FloMix Four Basic Models

TECHNICAL DATA TABLE

|

Parameter |

Valve |

|

Max Material Pressure (Low-Pressure System) |

100 psi (7 bar, 0.7 MPa) |

|

Max Material Pressure (High-Pressure System) |

2900 psi (200 bar, 20 MPa) |

|

Max Air Pressure |

100 psi (7 bar, 0.7 MPa) |

|

Proportion Range |

1-30:1, ±1% adjustable |

|

Flow Range |

20-3000 cc/min |

|

Viscosity Range |

20 - 5000 cps |

|

Noise |

< 75 dB (A) |

|

Power Supply |

AC 220 V, 50-60 Hz, 4 A |

|

Operating Temperature |

5 - 50°C (41 - 122°F) |

|

Dimensions |

1200mm × 800mm × 1650mm (reference) |

|

Apply Materials |

Solvent-Based Coatings, Water-Based Coatings, Acid-Catalyzed Coating Varnishes, etc. |

|

Wetted Parts |

316 Stainless Steel, FFKM, PTFE |