Key Features

• High mixing ratio capability up to 100:1.

• Accurate flow control with ±1% repeatability.

• Advanced mixing technology for uniform in plural-component blending.

• Available inpluralple configurations with precision ceramic cylinders.

• Wear-resistant coated piston rods ensure excellent service life.

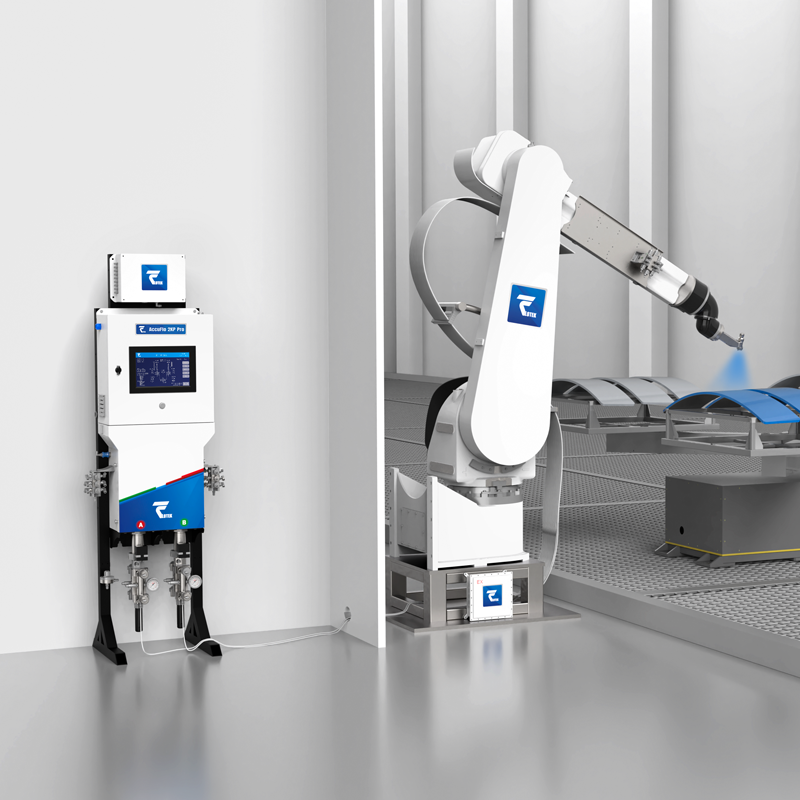

Why Choose AccuFlo 2KP Pro

• Reduces up to 80% of solvent and mixed paint waste, significantly reducing hazardous waste disposal costs.

• Faster color change capability improves flexibility and production efficiency.

• Integrated fluid pressure control ensures optimal spray performance and reduces coating consumption.

• Durable components designed for long life and minimal maintenance requirements.

Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

TECHNICAL DATA TABLE

|

Parameter |

Value |

|

Max Material Pressure (Low-Pressure System) |

300 psi (21 bar / 2.1 MPa) |

|

Max Material Pressure (High-Pressure System) |

1500 psi (105 bar / 10.5 MPa) |

|

Max Air Pressure |

100 psi (7 bar / 0.7 MPa) |

|

Proportion Range |

0.1:1 to 100:1, ±1% |

|

Flow Range |

20–800 ml/min |

|

Repeatability |

±1% |

|

Viscosity Range |

20–5000 cps |

|

Noise |

<75 dB(A) |

|

Power Supply |

AC 220 V, 50–60 Hz, 4 A |

|

Operating Temperature |

5–50°C (41–122°F) |

|

Dimensions |

Wall-mounted split type: 520mm × 560mm × 2000mm (reference) |

|

Apply Materials |

Single- orplural-component, solvent-based and water-based coatings, polyurethane, epoxy, acid-catalyzed varnish, etc. |

|

Wetted Parts |

316 Stainless Steel, Ceramics, Composite Materials, FFKM, PTFE |