Features

• Wide ratio range up to 50:1 with ±1% accuracy

• pluralple model configurations with integrated flow meters

• Straight-through flow channel design minimizes material retention

• Fast system response for real-time process control

• Compact, modular structure for efficient installation and space saving

Advantages

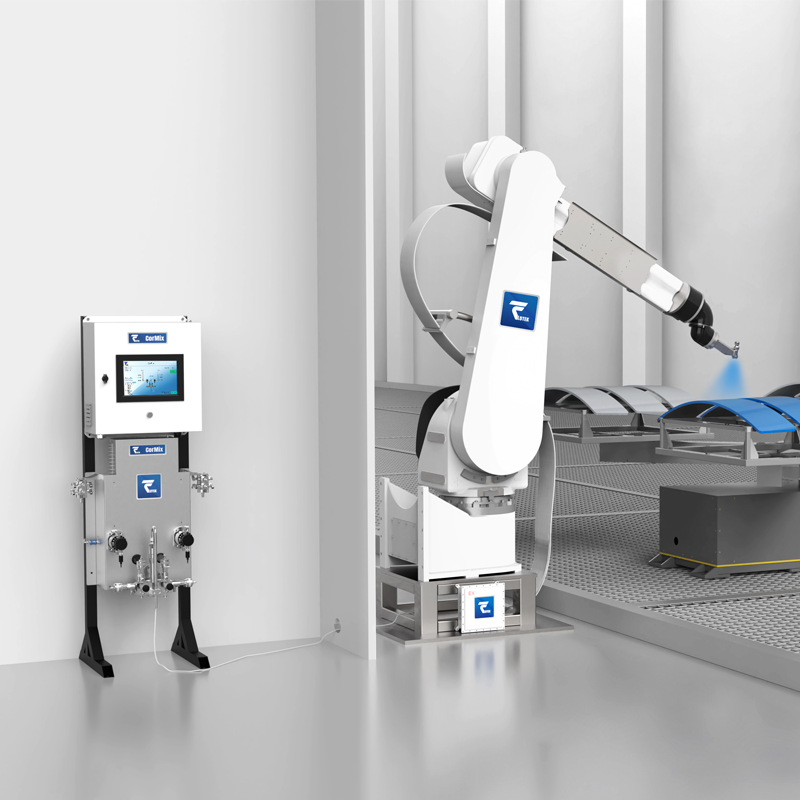

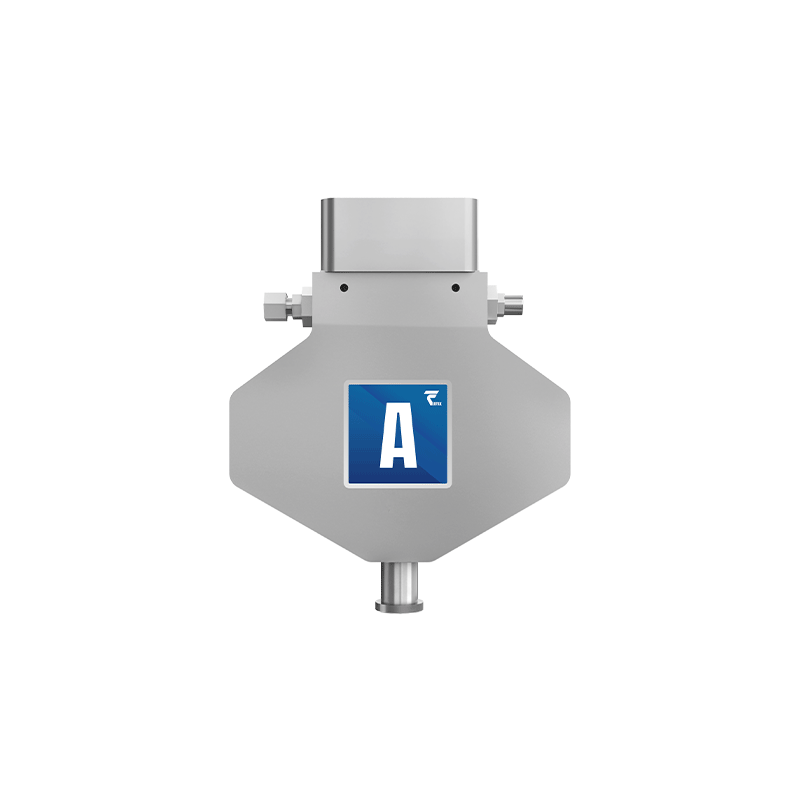

• Automatic color change and cleaning via modular CCV color change valve

• Seamless integration with Cormix control system for future scalability

• Accurate mixing ratios: from 0.1:1 to 50:1, with ±1% precision and 0.1-step control

• User-friendly interface for proportioning, calibration, cleaning, diagnostics

• Supports pluralple industrial communication protocols: Discrete I/O, Modbus, Profinet, EtherCAT

• Reduces setup, layout, and transport costs through smart compact design

|

|

|

|

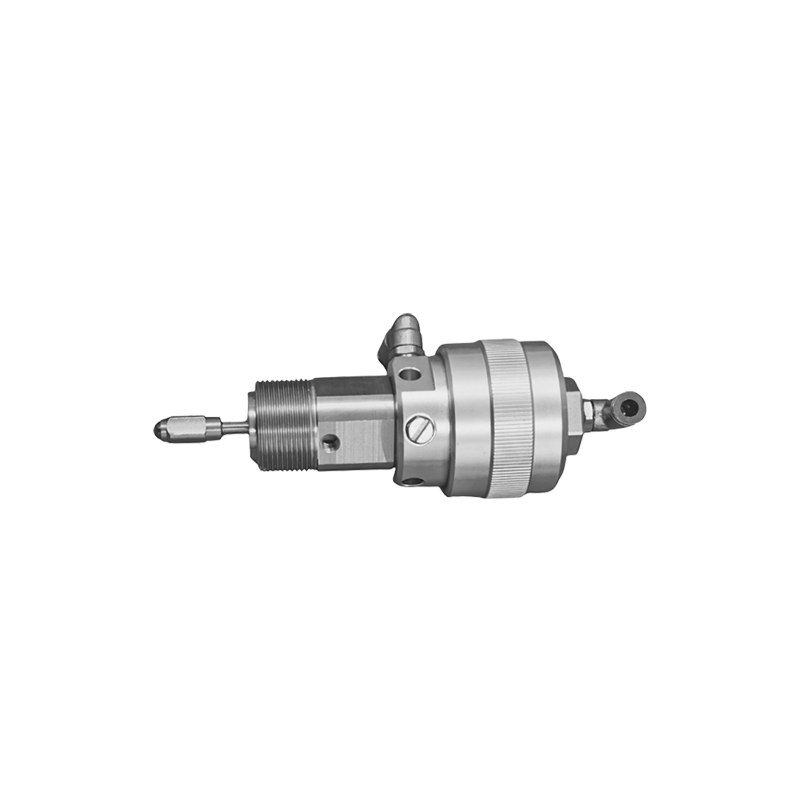

Double acting high-pressure fluid valve |

Double acting high-pressure fluid valve |

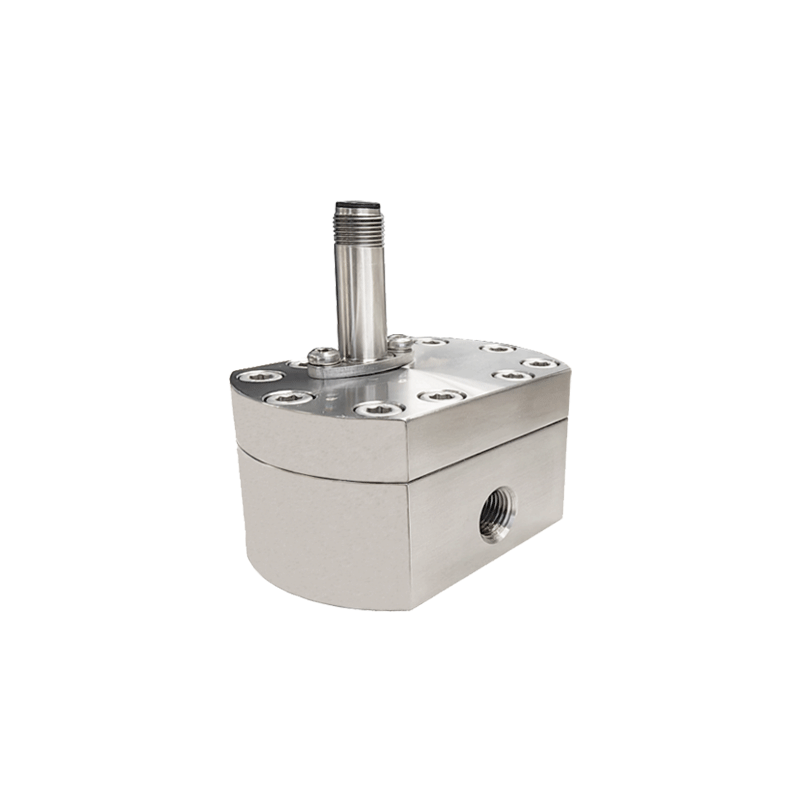

Mass flowmeter |

Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

TECHNICAL DATA TABLE

|

Parameter |

Value |

|

Max Materials Pressure (Low-Pressure) |

300 psi (21 bar / 2.1 MPa) |

|

Max Materials Pressure (High-Pressure) |

2900 psi (200 bar / 20 MPa) |

|

Max Air Pressure |

100 psi (7 bar / 0.7 MPa) |

|

Proportion Range |

0.1:1 to 50:1, ±1% |

|

Flow Range |

20–3800 cc/min |

|

Viscosity Range |

20–5000 cps |

|

Noise |

<75 dB(A) |

|

Power Supply |

AC 220 V, 50–60 Hz, 4 A |

|

Operating Temperature |

5–50°C (41–122°F) |

|

Dimensions |

Wall-mounted split type: 520mm × 560mm × 1730mm (reference) |

|

Apply Materials |

Solvent-based, water-based, acid-catalyzed coatings, varnishes |

|

Wetted Parts |

316 Stainless Steel, FFKM, PTFE |