Features

• Up to 30-color integration with compact color change valves and gear pump assemblies

• Multiple configurations available, featuring titanium-coated gear pumps for durability

• Long-life diaphragm-type color change valve on hardener side

• High-precision flow control with ±2% accuracy

• Fast response time and rapid color switching capability

|

|

|

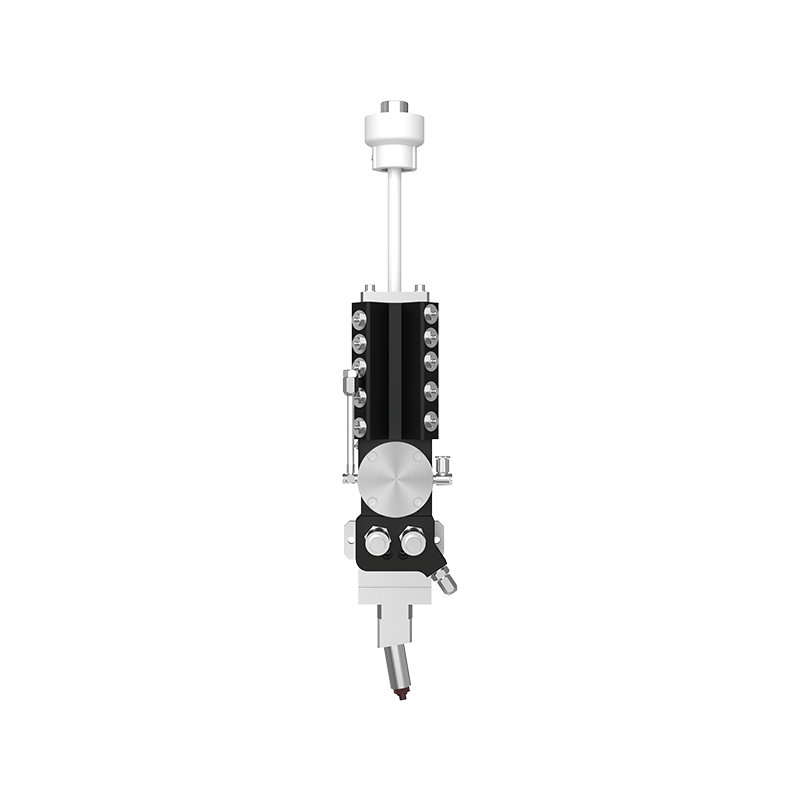

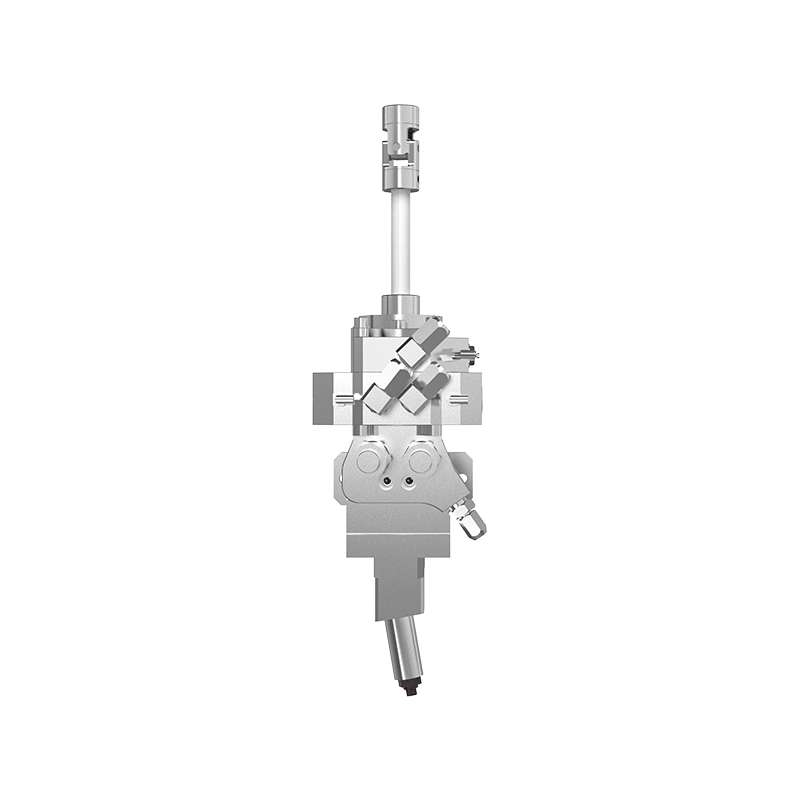

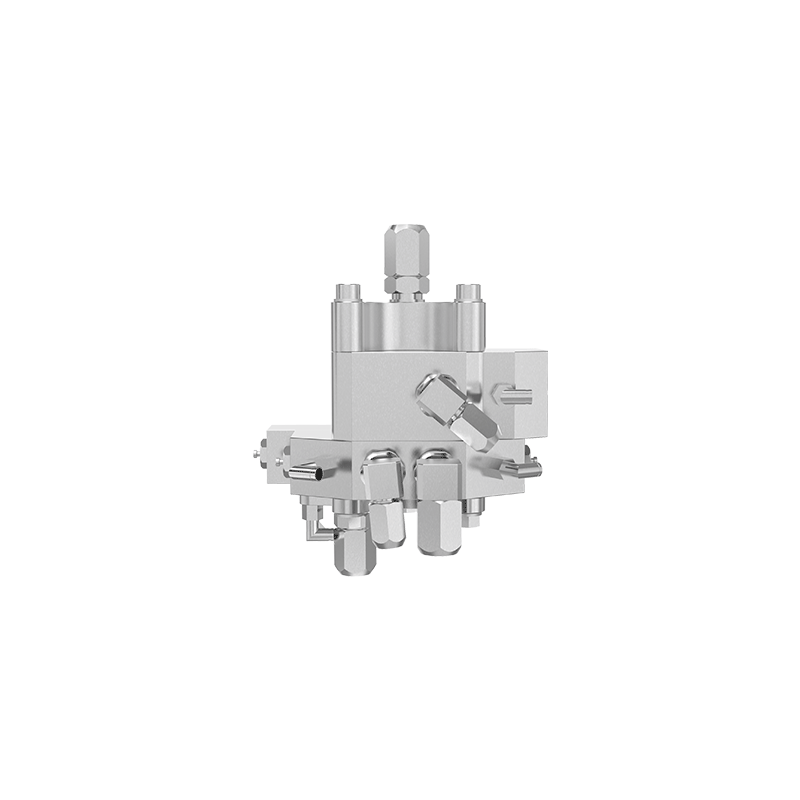

| Resin side | Hardener side | Mixer |

Advantages

• Proprietary intelligent spray software developed over years of refinement offers smart, fast, and reliable control

• Explosion-proof design options: built-in motors, external explosion-proof servos, and pressure sensors

• Compact and lightweight color change modules allow easy integration and modular design,easy for future extending

• Integrated atomizer process control box, including control functions: color change valves, atomizers and processes

Typical Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

TECHNICAL DATA TABLE

|

Designation |

Value |

|

MaxMaterialPressure |

300 psi (21 bar / 2.1 MPa) |

|

Max Air Pressure |

145 psi (10 bar / 1.0 MPa) |

|

Proportion Range |

1:1 to 30:1, ±2% |

|

Flow Range |

1KG: 10–1000 ml/min; 2KG: 20–1200 ml/min ±2% |

|

Viscosity Range |

20–5000 cps |

|

Noise |

<75 dB(A) |

|

Operating Temperature |

5–50°C (41–122°F) |

|

Apply Materials |

Solvent-/water-based coatings, polyurethane, epoxy, varnish |

|

Wetted Parts |

Stainless Steel, Composite Materials, PFPE, PTFE |