Features

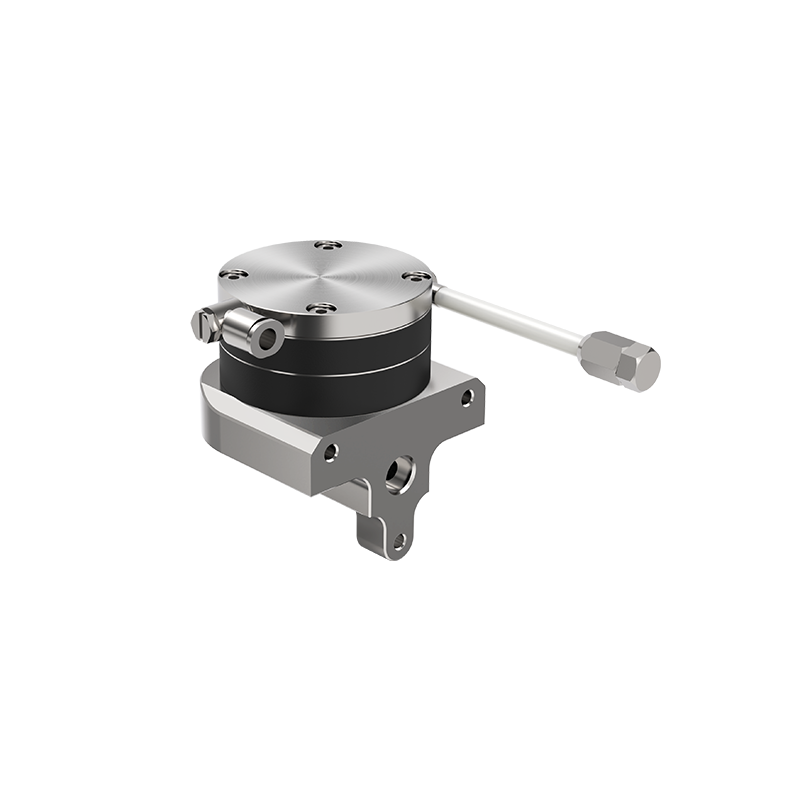

• All-316 Stainless Steel Construction: Corrosion-resistant and electrolytically polished for durability in demanding industrial environments.

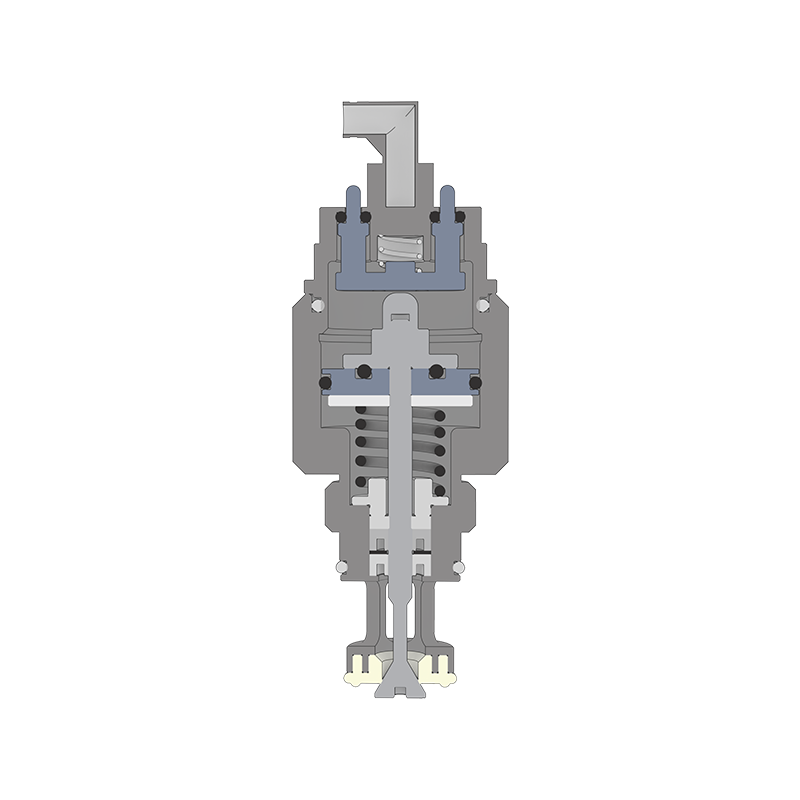

• Eecellent flow fluid passage : Straight-through needle alignment with the fluid channel ensures minimal paint retention, faster color changes, and easy flushing.

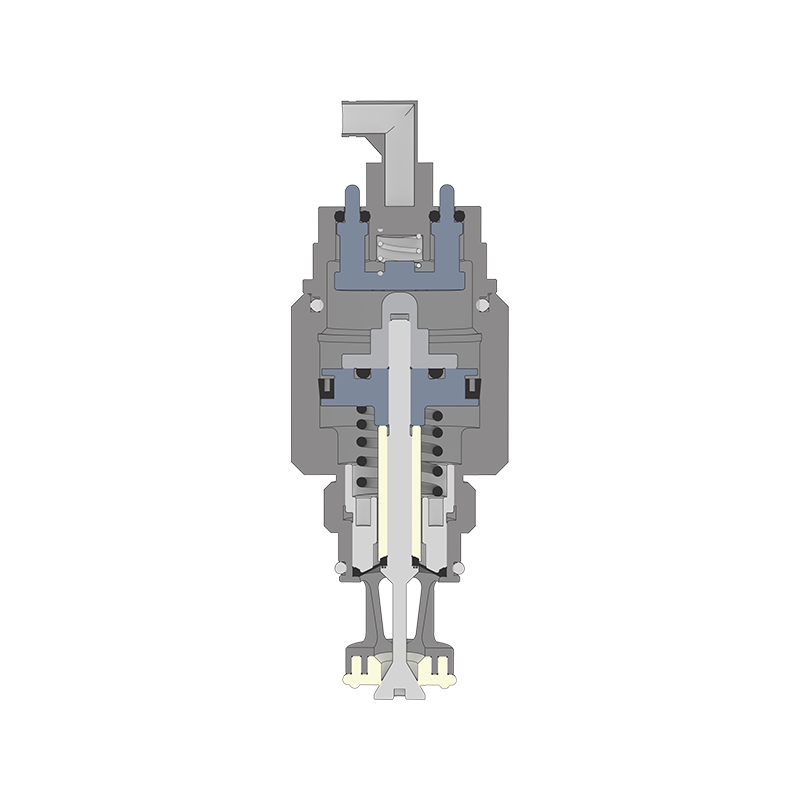

• Premium Seal Materials: Equipped with a high-performance FFKM sealing seat that delivers excellent chemical resistance, tight shut-off, and long operational life.

• Recirculating Seat Design: Promotes constant paint circulation through the valve to prevent pigment sedimentation during standby or color change.

• Precision-Machined Components: Built for long-term reliability, rated for over 1 million cycles depending on material types.

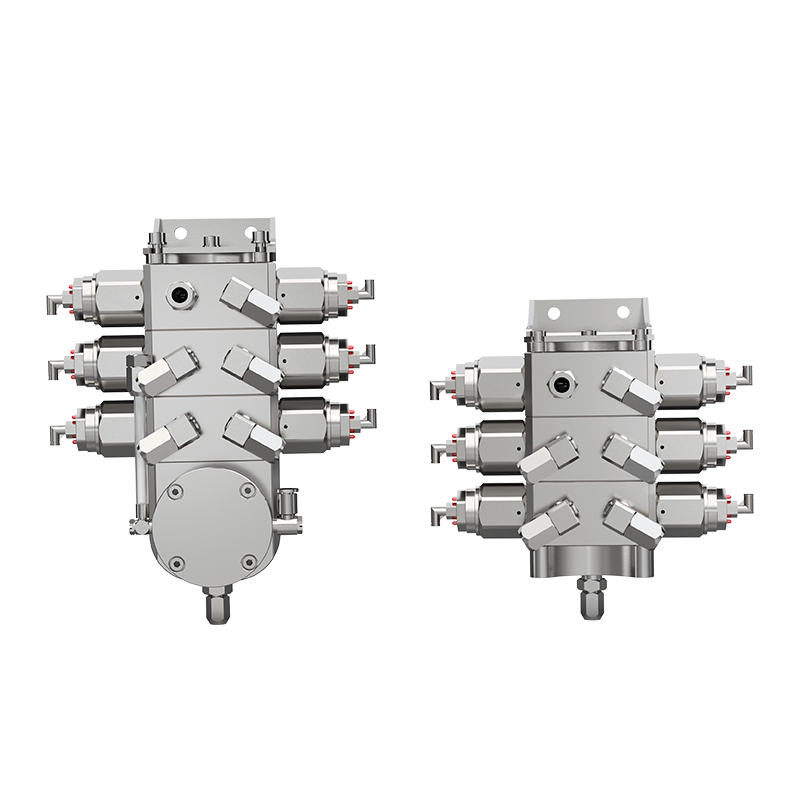

• Quick Maintenance: Modular design allows for fast assembly/disassembly and easy system expansion or reconfiguration.

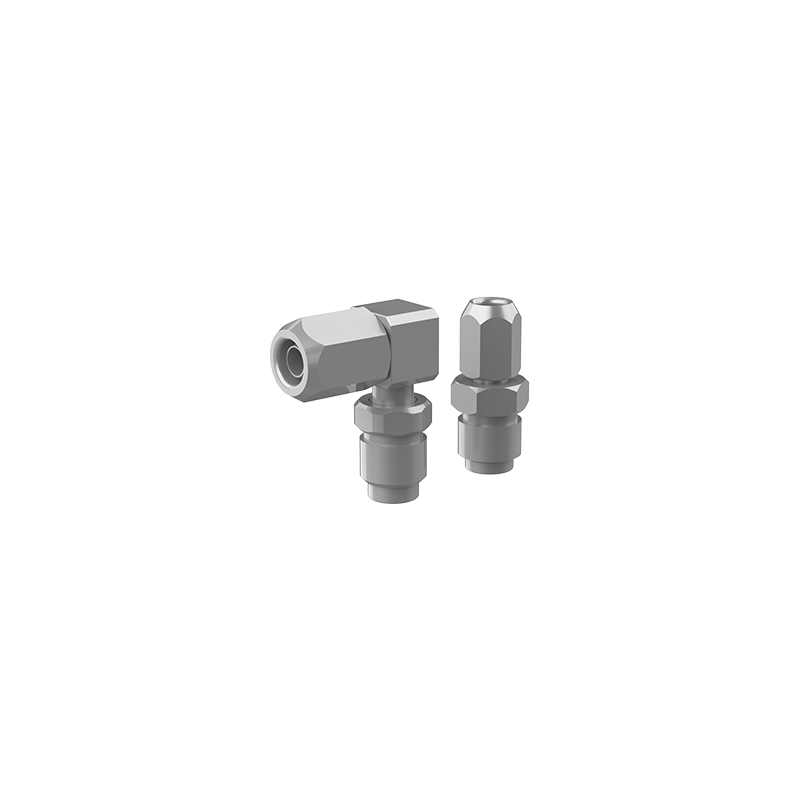

• Cavity Free Fluid Adaptor: Seamless channels with no tape-sealed joints eliminate dead spots and contamination risks. Universal stainless-steel fluid fittings included.

|

|

|

|

|

Hose connector |

Diaphragm type |

Needle type | Module fluid regulator |

Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

TECHNICAL DATA TABLE

|

Designation |

Value |

|

Max Material Pressure |

300 psi (21 bar / 2.1 MPa) |

|

Max Air Pressure |

100 psi (7 bar / 0.7 MPa) |

|

Fluid Inlet / Outlet |

1/4" G (F) – Hose connector optional |

|

Fluid Recirculation |

1/4" G (F) – Hose connector optional |

|

Air Inlet Size |

Ø4 mm × 2.5 mm |

|

Operating Temperature |

5–50°C (41–122°F) |

|

Apply materials |

Primers, topcoats, varnish, polyurethane, epoxy, solvent- borneand water-based coatings |

|

Wetted Parts |

316 Stainless Steel, FFKM, UHMWPE |