Features&Advantages

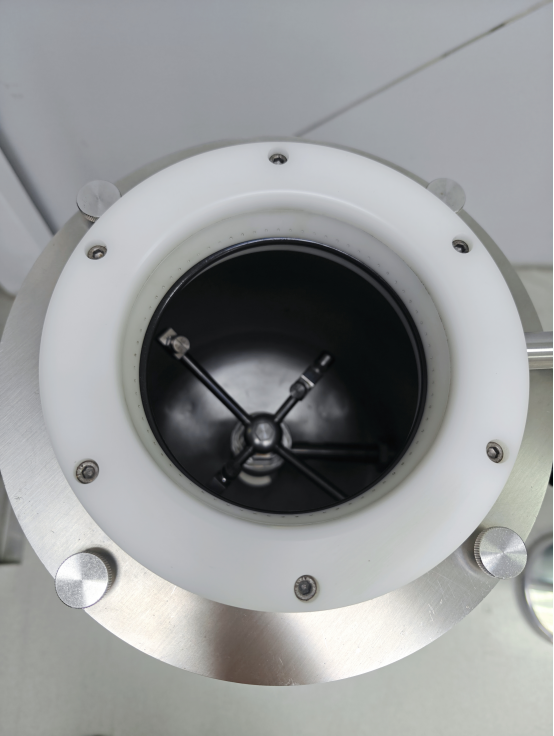

360 ° flushing nozzle

Rotating impeller design, 360 air and solvent alternating flushing nozzle. Sealed ring prevent solvent leakage.

Quick disassembly structure, easy to clean

Quick screw design. It can quickly clean the inside of the barrel, with a polished stainless steel barrel body and open discharge.

Safety explosion-proof

The whole machine adopts pneumatic design, and the impeller adopts mechanical ceramic bearings. Stainless steel pneumatic valves are used for fluid and air switching. the equipment is ground- supported design, safe and explosion-proof operation can be achieved.

Small size, easy to deploy

The barrel body with a diameter of 250mm occupies a small space, and the standardized discharge interface is easy to recycle waste liquid.

Applications

• Auto Parts

• Furniture & Wood Finishing

• Sanitary Ceramics & Bathroom Products

•3C

•General Industrial: Hardware, Plastics, and More

TECHNICAL DATA TABLE

|

Designation |

Value |

|

Max Material Pressure (low-pressure system) |

300 psi(21 bar,2.1 MPa) |

|

Max air pressure |

100 psi(7 bar,0.7 MPa) |

|

Solvent inlet size |

(φ6*8) |

|

Air inlet size |

(φ6*8) |

|

Valve controls the size of the air pipe |

(φ4*2.5) |

|

Operating Temperature |

5 - 50°C(41 - 122°F) |

|

Size |

φ250mm*H620mm |

|

Apply Materials |

Single component, solvent based and water-based coatings, polyurethane, epoxy resin, etc |

|

Wetted Parts |

316 stainless steel, 304 stainless steel,FFKM、PTFE |

|

Max solvent consumption |

150cc |

|

Weight |

About 10Kg |